ECT – Electromagnetic Casting Table for casting aluminum billets

More than 80 percent of the aluminum used worldwide in extruded sections are aluminum alloys. The production of billets for aluminum extrusion requires a certain degree of homogeneity. In DC casting process (standard casting process) there are segregated particles inside thecast structure of the billets.

The billets cast with ECT have smooth surface, the structure is very fine and amazing homogeneity with small globular grain without boundarysegregation. Also ECT eliminates macro porosity and has good influence on grain refining.

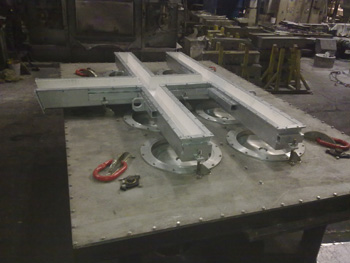

Casting tables:

20 pieces

Billet dimension:

6” – 25”

References:

Serbia, Bosnia and Herzegovina, Macedonia, Italy, Iran

Casting Aluminum Billets in Low-Frequency Electromagnetic Field

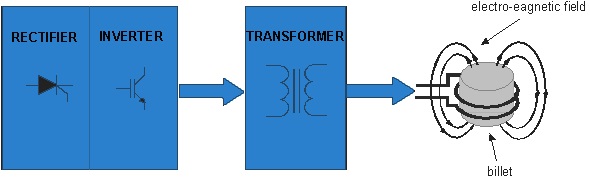

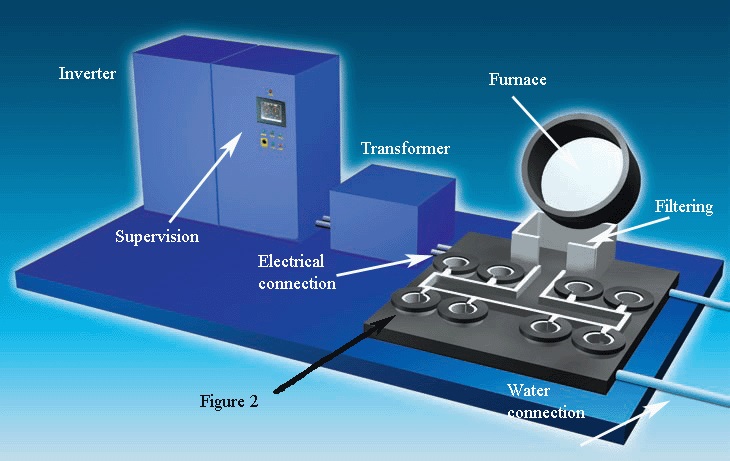

When alternating current flows thought a coil, a varying electro-magnetic field is generated. The varying electro-magnetic field induces eddycurrent in the conducting materials. In the Electromagnetic Casting process, the alternating current generates time varying electro-magneticfield in the melt and billets. The forces caused by the interaction of the induced current and the electromagnetic field resulting flow in the meltand potential forces which is balanced by static pressure of the melt. The consequence of this is the formation of a convex surface (meniscus) anddecrease in the contacting pressure on the mold (soft contact). This results in good surface. Application of varying electro-magnetic field on casting Al billets significantly improves the microstructure, surface quality and decrease grain boundary segregations. The schematic diagram of the Electromagnetic Casting process is shown on the Figure 2. The ring shaped mold is made of an Al alloy. A graphite ring is embeddedin the top side of the Al alloy mold. The electromagnetic field is applied through the induction coil with the number of ampere turns 18 000 At and frequency from 1 to 100Hz.

Compared with billets cast in the standard casting process, microstructure of billets cast in electromagnetic field is fine and uniform.

Advantages consideration for ECT:

- Smooth surface.

- The structure is very fine with very good homogeneity and small globular grain.

- Segregation zones absence.

- ECT eliminates macro porosity and has good influence on grain refining.

- All these points indicate homogeneity within structure and absence of segregation, so extrusion without heat treatment is possible.

Supervision, data acquisition and logging